Tableware

In the “platicXchange” project, we worked with students from the German University of Cairo (GUC) to develop an idea for tableware. Together with Sara Wagdy | GUC, Yara Reda | GUC, Frederik Wrede | HSOS, and Moritz Ebbrecht | HSOS, we produced three concepts.

Extensive Research at Both Universities

We conducted extensive research at both universities, focusing on the topic of tableware and how students currently store and transport their food. This investigation began with an assessment of the current state: we observed how students package their meals and which solutions they typically use on a day-to-day basis. We also explored how other individuals, such as working professionals, manage their meal storage needs.

In addition, we analyzed how larger companies and organizations approach tableware and packaging solutions, learning from both their successes and their challenges. Our research identified several best practices as well as shortcomings in existing systems, highlighting key areas where design improvements are needed.

Through this comprehensive analysis, we pinpointed critical pain points and opportunities for innovation in tableware design, ensuring our project addresses real-world problems and meets the needs of our target users.

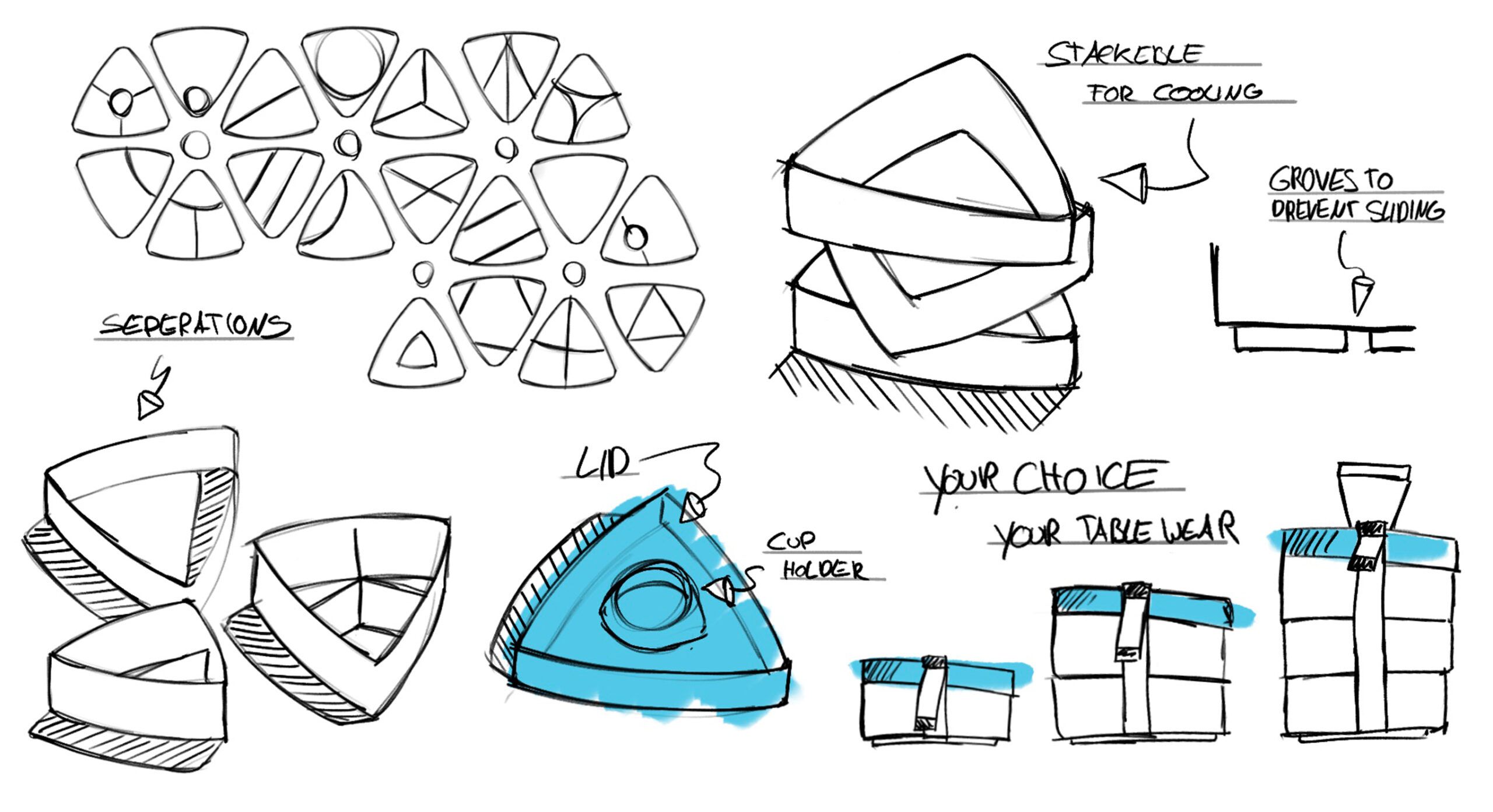

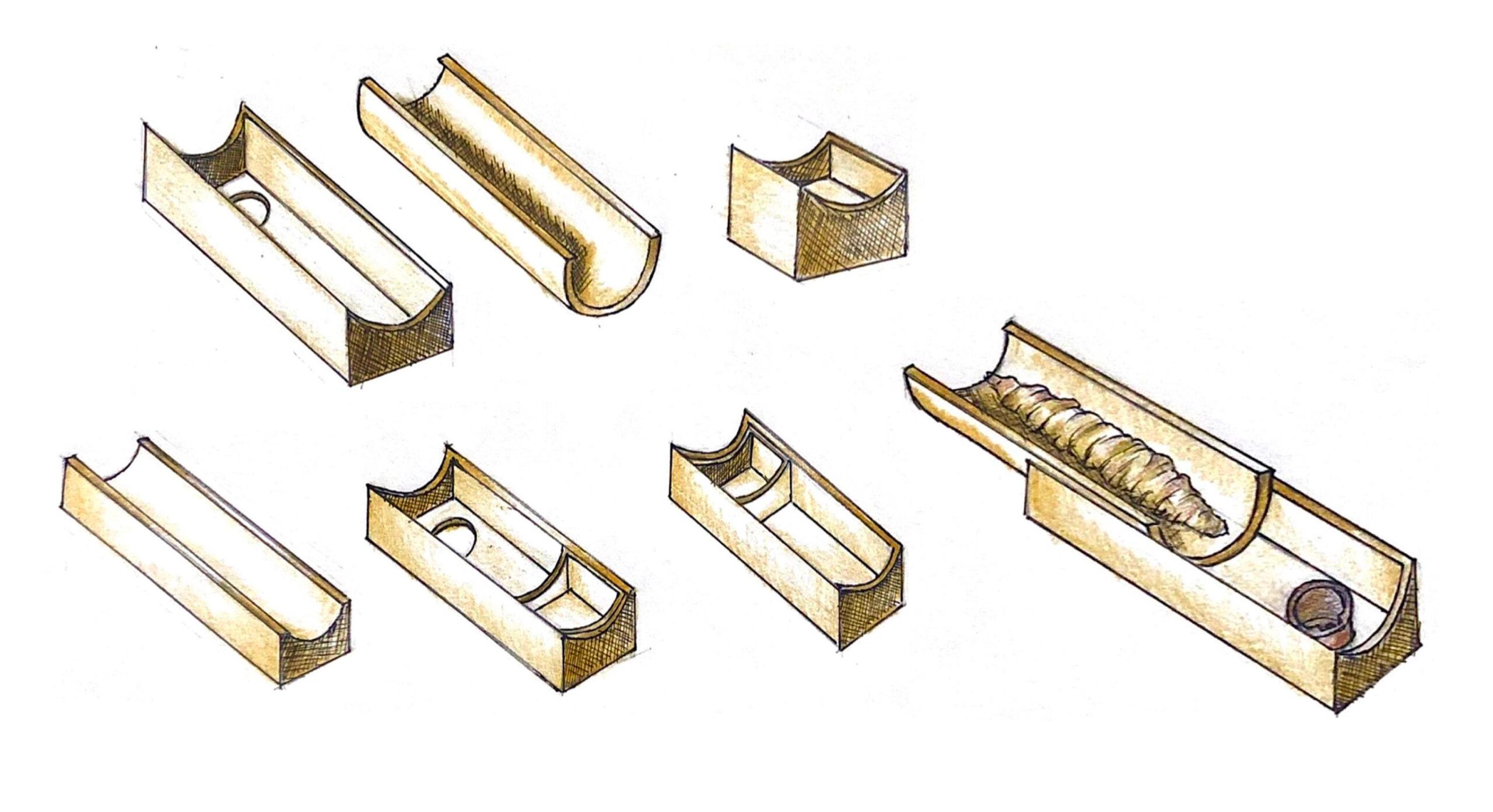

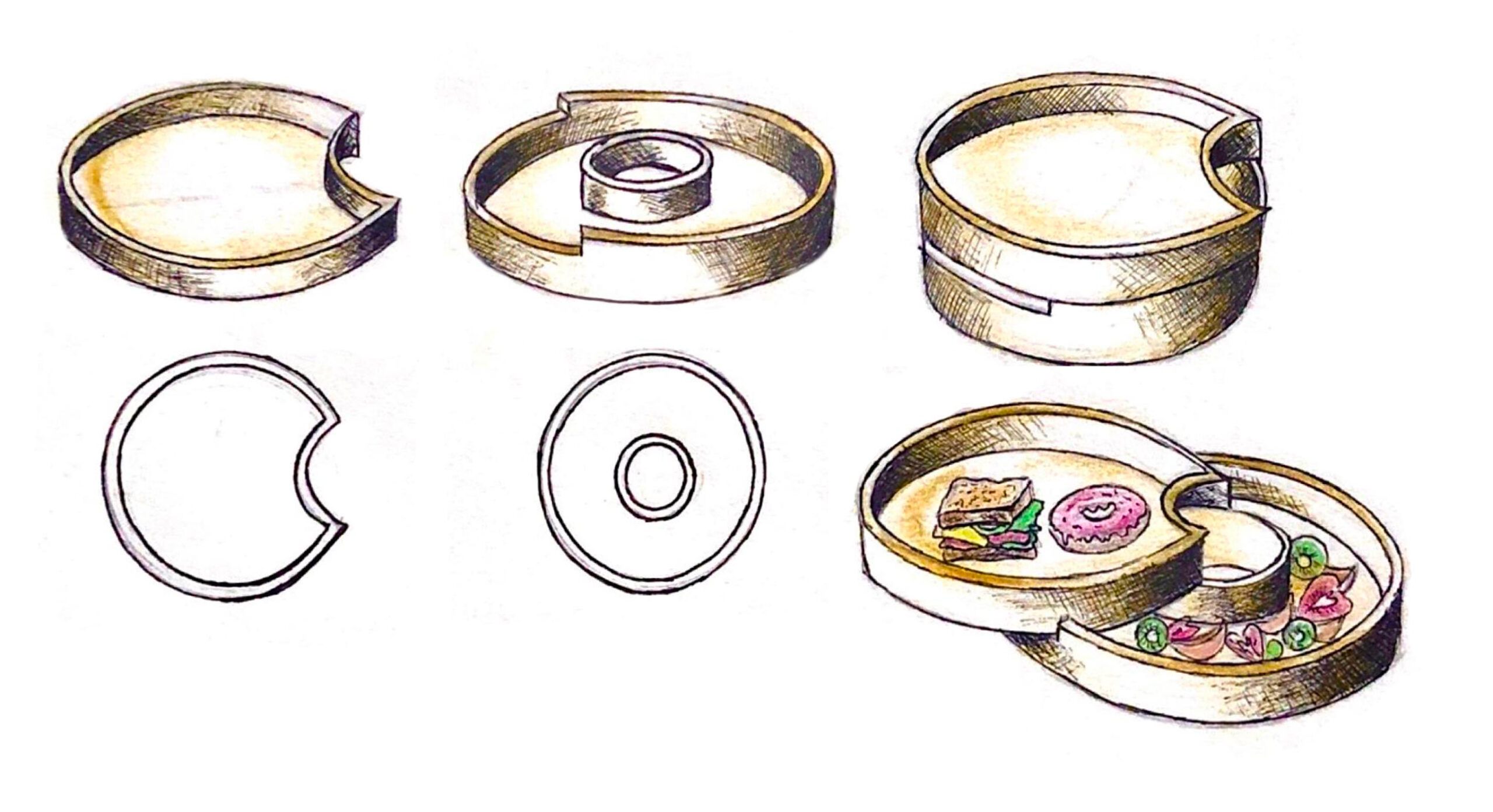

The Functionality Behind Our Concept

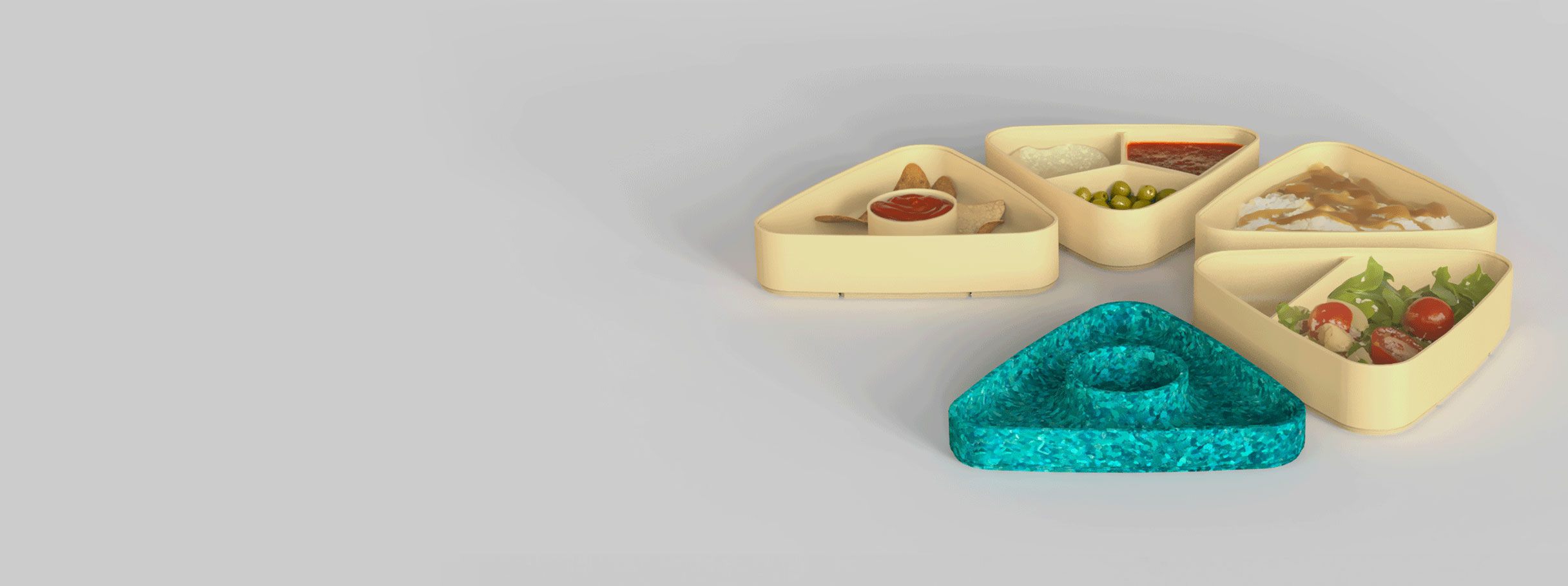

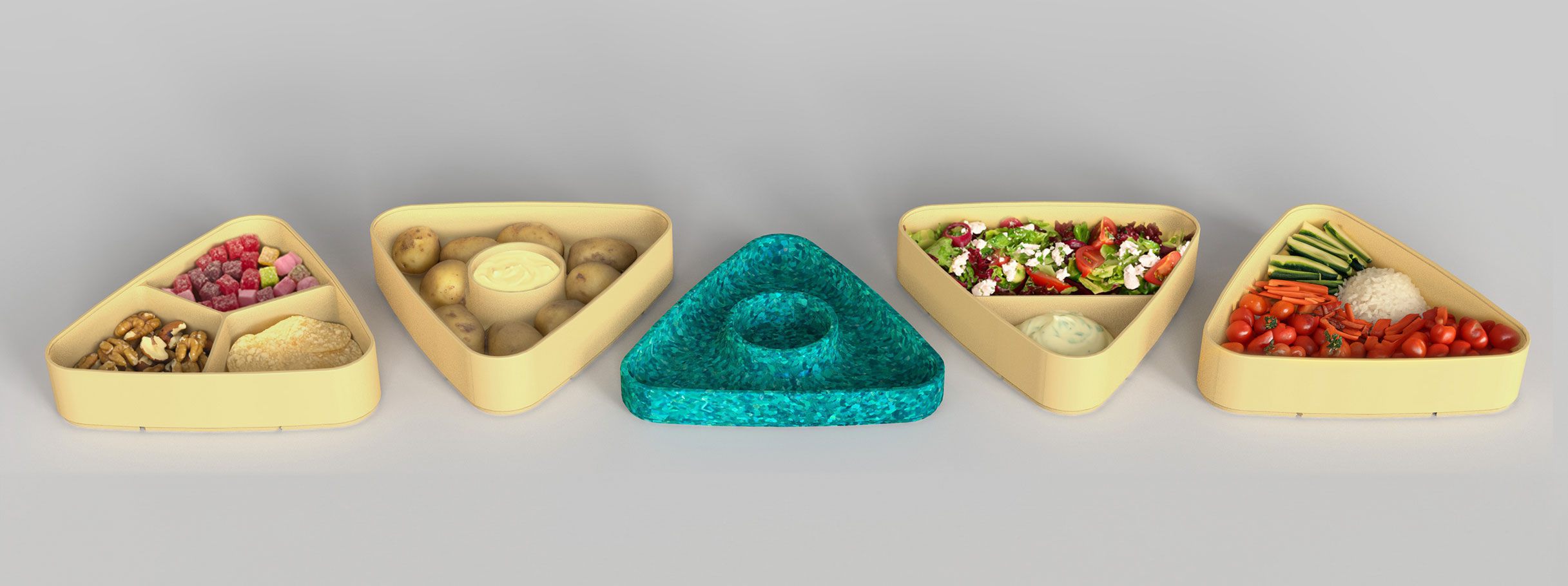

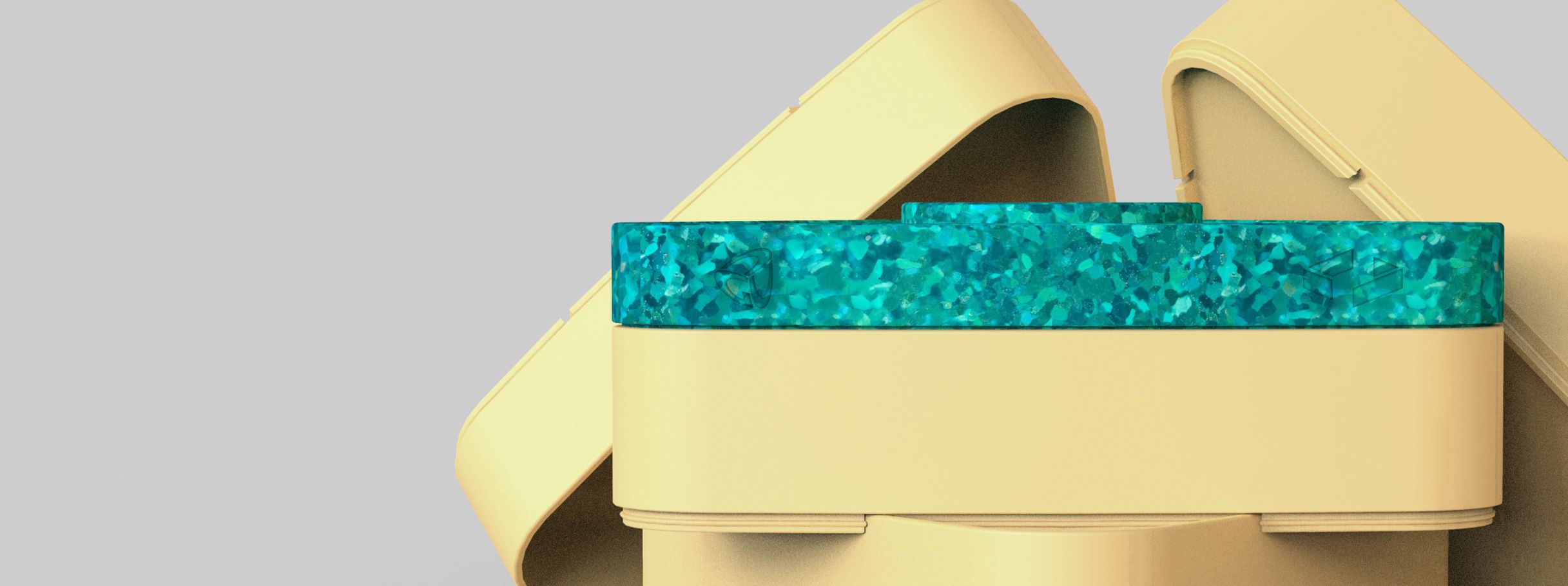

The idea behind the tableware is straightforward. Individual lunch boxes can be created by combining several components. Depending on what is required, these can be gradually added. The tableware is displayed offset in order to cool off heated meals. An elastic band is wound around the boxes end to join the various parts together.

Your tableware, your choice.

No matter how much you want to take with you, the lunch box is always the right size.

With its many different components, the food is optimally separated from each other.

Sustainable Materials

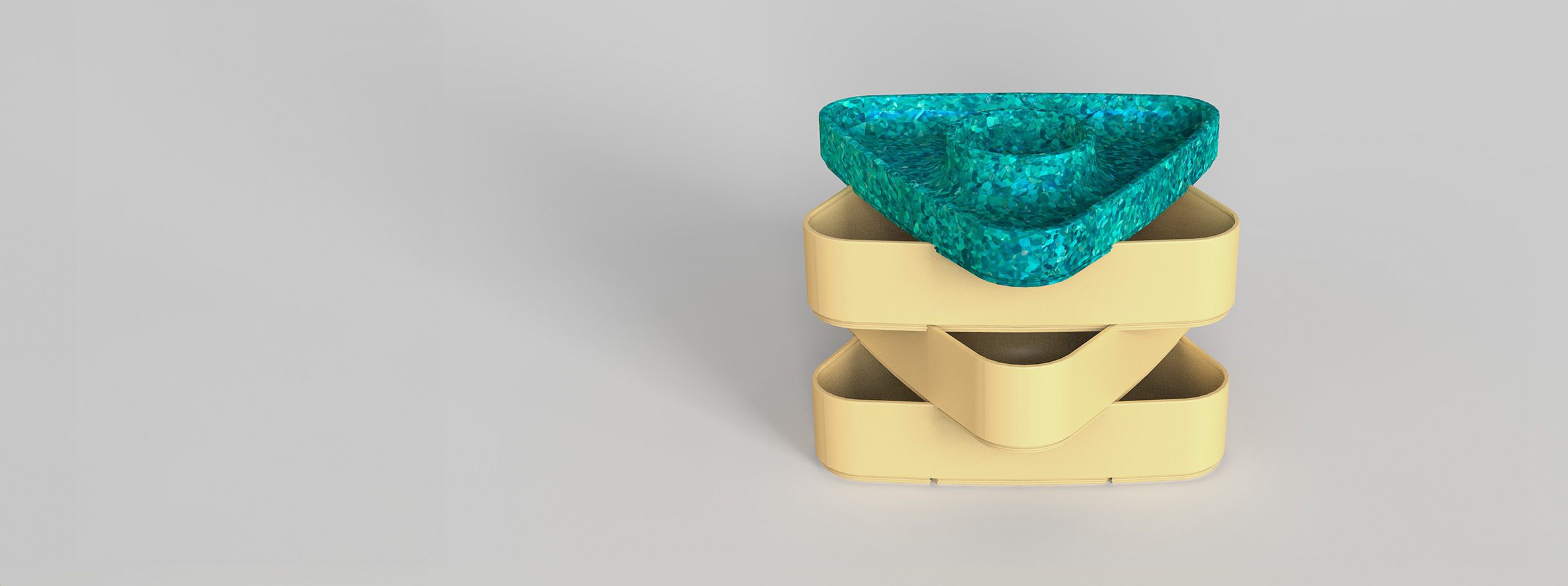

The lunchbox is made from high-quality recycled materials, helping to reduce environmental impact and promote a circular economy. By choosing sustainable resources, we ensure that our product is both functional and environmentally conscious, aligning with modern values of responsible consumption.

Rapid Prototyping for the Lunchbox Design

After we had finalized the design of our lunchbox, we decided to construct a rapid prototype to quickly test and evaluate our concept. This step allowed us to assess the handling, ergonomics, and usability of the product in a practical way, ensuring that the design met our expectations before moving on to final production.

To bring this prototype to life, we chose to use 3D printing as our fabrication method. 3D printing is a versatile, efficient, and cost-effective way to produce models for design verification and user testing. It provided us with a stable and sufficiently detailed representation of the product, while significantly reducing production time compared to traditional prototyping methods.

For the 3D print, we selected Extrudr’s high-quality matte finish filament, which delivered a professional look and feel while being easy to post-process. The model was printed on the Ender 2 printer, known for its reliability and precision, especially in small batch prototyping.

Once the prototype was complete, we conducted a thorough functionality check, filled it with food, and documented the process through photography. These photos not only showcased the product’s practicality but also served as valuable material for presenting the design and gathering feedback.